Can Ejector Pins Cause Defects on Molded Parts?

In the world of plastic injection molding, ejector pins play a vital role in ensuring that molded parts are cleanly and efficiently removed from the mold cavity. These slender, high-strength components are designed to push finished parts out once the molding process is complete.

More >>

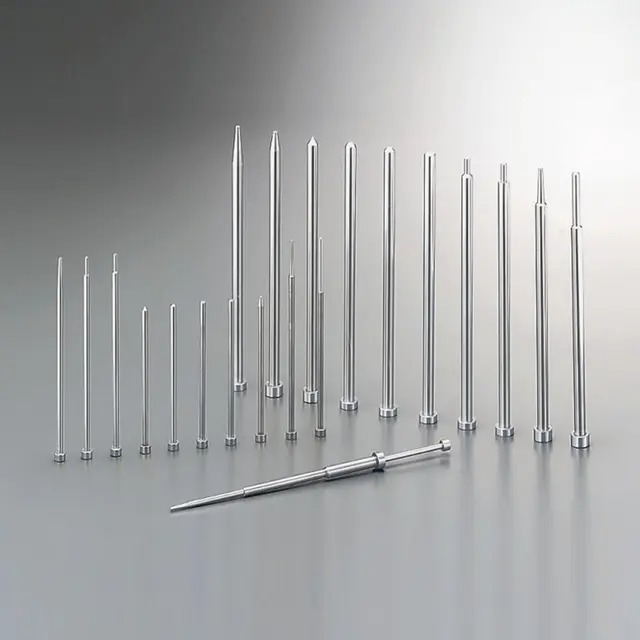

What Are Precision Carbide Pilot Punches And Why Are They Essential in Metalworking?

Precision carbide pilot punches are specialized tooling components designed for use in high-accuracy punching and forming applications, particularly in metal stamping, die making, and manufacturing environments where precision, durability, and wear resistance are paramount.

More >>

How Do You Select the Right Precision Carbide Pilot Punch?

When it comes to high-accuracy metal stamping, die making, or precision tooling applications, precision carbide pilot punches play an irreplaceable role.

More >>

Carbide Pilot Punches: What Makes Them Essential for Precision Tooling?

In precision tooling and manufacturing, the choice of punching tools directly affects product quality, operational efficiency, and tool lifespan. Among various punch types, carbide pilot punches stand out for their exceptional durability, accuracy, and resistance to wear.

More >>

Can Carbide Pilot Punches Be Repaired if Damaged?

Carbide pilot punches are precision-engineered tools used extensively in industries such as metal stamping, die making, and high-volume manufacturing. They are designed to create clean, accurate holes or pilot marks in workpieces, guiding subsequent operations with minimal deviation.

More >>

What is a Nitrogen Spring?

Nitrogen springs are a specialized type of industrial spring that utilize compressed nitrogen gas as the energy storage medium rather than conventional coiled metal.

More >>

Can Nitrogen Springs Replace All Coil Springs?

IntroductionA nitrogen spring is a high-pressure device that uses compressed nitrogen gas as the energy source to provide consistent and powerful force in mechanical operations.

More >>

What is the Best Material for an Ejector Sleeve?

In the world of precision tooling, ejector sleeves play an essential role in ensuring that molded or stamped components are released smoothly from the die or mold cavity.

More >>