Views: 192 Author: Site Editor Publish Time: 2025-08-14 Origin: Site

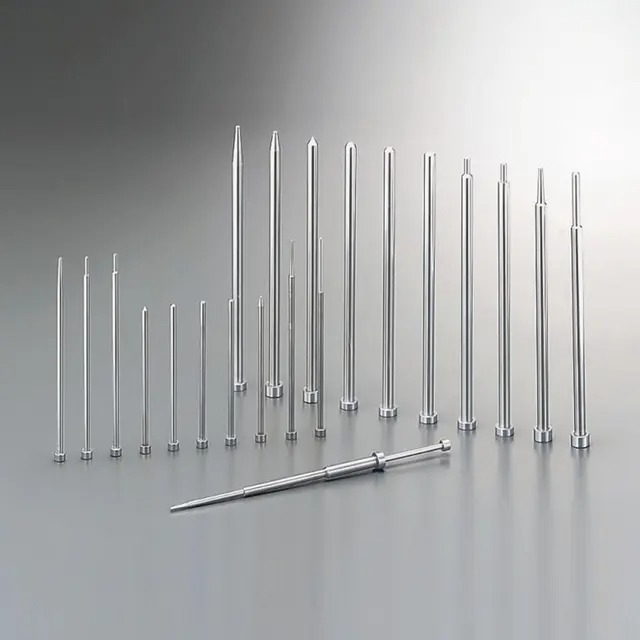

In the world of precision tooling, ejector sleeves play an essential role in ensuring that molded or stamped components are released smoothly from the die or mold cavity. These cylindrical components are designed to fit over ejector pins, applying even pressure to the finished part during the ejection process. Without them, parts might stick, deform, or suffer from surface damage during removal. In industries such as automotive, aerospace, electronics, and consumer goods manufacturing, ejector sleeves contribute directly to both production efficiency and product quality.

The fundamental job of an ejector sleeve is deceptively simple: to assist in removing a finished part from the mold or die. However, in practice, the engineering requirements are far more complex. An ejector sleeve must be manufactured with extreme precision to ensure a perfect fit within the mold assembly, minimize friction, and withstand repeated mechanical stress. It must also endure elevated operating temperatures, particularly in die-casting or injection molding applications, where thermal expansion and wear resistance are constant concerns.

Selecting the right material for an ejector sleeve is one of the most critical decisions a tooling engineer can make. The choice influences not only the lifespan of the sleeve but also the overall performance of the tooling system. A material with inadequate hardness might deform under pressure, while one with insufficient thermal stability could warp during prolonged high-temperature cycles. Conversely, an overly brittle material may crack under the repetitive mechanical load.

This is why material selection is never an afterthought. It must balance several factors—hardness, thermal resistance, wear properties, machinability, and cost efficiency. For instance, high-performance tool steels like SKD61 are widely recognized for their ability to deliver exceptional durability, even in demanding conditions. However, other alloys and treatments may be suitable depending on the application’s specific requirements. Understanding the properties and trade-offs of various materials is the foundation for identifying the “best” choice for your ejector sleeve needs.

The process of choosing the best material for ejector sleeves involves evaluating a range of mechanical and operational factors. Each parameter contributes to the overall performance and longevity of the sleeve in a production environment.

1. Hardness and Wear Resistance

Since ejector sleeves are subjected to constant sliding movement and repetitive mechanical contact, they require materials with excellent surface hardness and wear resistance. Hardened tool steels and alloy steels are common because they resist abrasive wear and surface pitting. A higher Rockwell hardness rating generally correlates with longer service life, provided the material is not overly brittle.

2. Heat Resistance

In high-temperature molding processes, such as die-casting aluminum or zinc alloys, the sleeve is exposed to molten metal temperatures that can exceed 600°C. Materials must retain their strength and hardness at these elevated temperatures, avoiding thermal fatigue and softening over time. Heat-treated steels with high chromium and molybdenum content often excel here.

3. Corrosion Resistance

While not always the first consideration, corrosion resistance becomes important in environments where the sleeve may encounter moisture, cooling fluids, or chemically reactive materials. Stainless tool steels and nitrided surfaces can help mitigate oxidation and corrosion.

4. Machinability and Surface Finish

Ejector sleeves require tight tolerances and smooth internal surfaces for optimal function. A material that machines well allows for precision manufacturing without excessive tool wear. The smoother the bore surface, the less friction is generated during part ejection, minimizing wear on both the sleeve and the mating pin.

5. Cost Efficiency

Premium materials often deliver the best performance, but they also come at a higher price. For large-scale production runs or less demanding applications, a cost-performance balance may favor slightly less expensive steels, especially if they still meet the operational requirements.

Ultimately, the “best” material is context-dependent, but modern industry trends show a preference for high-alloy tool steels such as SKD61 (equivalent to H13 in some standards) because of their exceptional blend of wear resistance, toughness, and thermal stability.

Below is a comparative table showing common materials used for ejector sleeves, along with their key characteristics. This serves as a reference point for engineers and buyers evaluating their options.

| Material Type | Hardness Range (HRC) | Heat Resistance | Wear Resistance | Machinability | Typical Applications |

|---|---|---|---|---|---|

| SKD61 (H13 equivalent) | 48–52 | Excellent (up to 600°C) | High | Good | Die-casting, injection molding |

| SKH51 (M2 HSS) | 60–65 | Very High | Excellent | Moderate | High-precision molds, cutting tools |

| SUS420 Stainless Tool Steel | 48–52 | Moderate | Moderate | Good | Corrosion-prone environments |

| Nitrided Alloy Steel | 50–55 (surface) | High | High | Good | Long-run production molds |

| Pre-Hardened Alloy Steel | 28–34 | Moderate | Moderate | Excellent | Low-volume or prototype molds |

From this comparison, it’s clear why SKD61 is often cited as the leading choice—it offers an exceptional combination of mechanical strength, heat resistance, and wear performance, making it ideal for demanding die-casting and injection molding operations.

SKD61 tool steel, recognized internationally for its superior performance, has become a benchmark material in ejector sleeve manufacturing. This steel is characterized by high toughness, excellent resistance to thermal fatigue, and the ability to maintain its properties under repeated heating and cooling cycles. Its chemical composition, rich in chromium, molybdenum, and vanadium, provides a balance of hardness and toughness rarely matched by other alloys.

In practice, SKD61 sleeves withstand the extreme temperatures of molten metals without losing shape or surface quality. Its resistance to heat checking—a network of small cracks caused by thermal cycling—ensures that the sleeve’s surface remains smooth over extended service life. This minimizes friction during part ejection, reducing wear on both the sleeve and the ejector pin.

Moreover, SKD61 responds well to surface treatments such as nitriding or PVD coatings, which can further enhance hardness and wear resistance without compromising toughness. This adaptability makes it a favorite for manufacturers who want to optimize performance for specific production conditions.

One of the additional advantages is its machinability. While harder than many steels, SKD61 can still be precision-machined to tight tolerances, allowing for the creation of complex geometries and smooth bore finishes that are essential for consistent ejection performance. When properly heat-treated, SKD61 offers a service life that justifies its higher cost compared to standard alloy steels, particularly in high-volume, high-heat applications.

For these reasons, SKD61 is often regarded as the “gold standard” material for ejector sleeves in the die-casting and injection molding industries.

While choosing the right material—such as SKD61—significantly impacts performance, proper maintenance practices are equally critical in extending the life of ejector sleeves. Even the best material will degrade prematurely if subjected to poor operational conditions.

Routine inspection is essential to identify early signs of wear, such as scratches, pitting, or discoloration from overheating. Cleaning the sleeves regularly to remove residues from molten metals or plastics prevents surface damage and buildup that could impede smooth movement. Lubrication is another critical factor; the use of high-temperature lubricants can reduce friction and wear between the sleeve and the ejector pin.

Additionally, alignment plays a vital role. Misaligned ejector systems create uneven wear patterns that can shorten service life. Ensuring precise installation and checking alignment periodically helps maintain performance consistency. For sleeves operating in corrosive environments, applying protective coatings or selecting corrosion-resistant steel grades can further enhance durability.

By pairing the optimal material with a well-structured maintenance program, manufacturers can maximize the return on investment in their ejector sleeve components and reduce unplanned downtime.

Q1: What is the primary function of an ejector sleeve?

An ejector sleeve surrounds the ejector pin and helps push the finished product out of a mold or die, distributing the ejection force evenly to prevent damage to the part.

Q2: Why is SKD61 commonly used for ejector sleeves?

SKD61 offers a high level of toughness, excellent thermal fatigue resistance, and strong wear resistance, making it ideal for high-temperature, high-volume production.

Q3: Can stainless steel be used for ejector sleeves?

Yes, stainless tool steels can be used, especially in corrosion-prone environments, but they may not match the heat resistance and wear performance of SKD61.

Q4: How can I extend the life of an ejector sleeve?

Regular cleaning, lubrication, inspection, and alignment checks are key maintenance steps to prolong the lifespan of an ejector sleeve.

Q5: Is the cost of SKD61 justified for all applications?

For high-volume, high-temperature production, SKD61 often pays for itself through longer service life and reduced downtime. However, for low-volume runs, more economical steels may suffice.