Views: 192 Author: Site Editor Publish Time: 2025-08-12 Origin: Site

An ejector sleeve is a critical component used in precision molding and die-casting applications, playing a key role in the ejection system of molds. Its main purpose is to remove finished parts from the mold cavity without damaging their shape or surface. Designed to work in harmony with ejector pins, the ejector sleeve provides uniform force distribution during ejection, which helps maintain the dimensional accuracy of molded products. In high-volume manufacturing, where molds may produce thousands of components daily, the performance of ejector sleeves directly impacts production efficiency, product quality, and tool longevity.

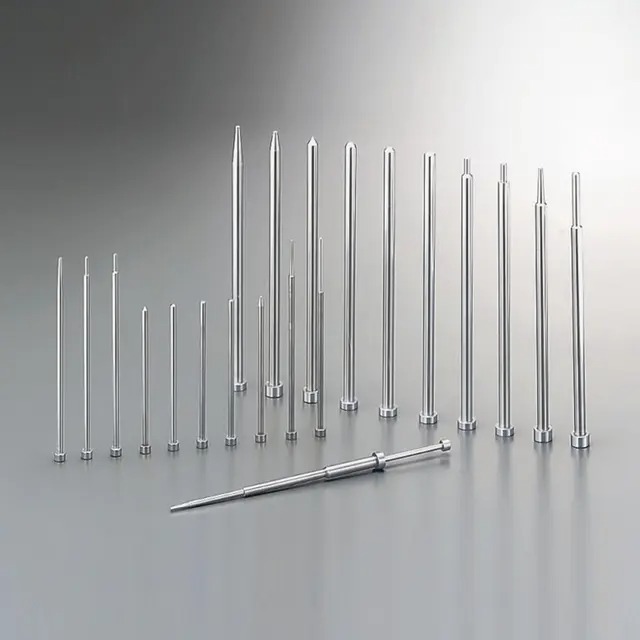

Unlike standard ejector pins, ejector sleeves feature a tubular design that fits over a core pin or core insert, allowing for smooth removal of parts with internal cores or complex shapes. This design is especially useful for parts with holes, recesses, or deep cavities where standard pins might cause deformation. Modern ejector sleeves are manufactured from high-grade tool steels such as SKD61, which provides excellent hardness, wear resistance, and thermal stability. With proper lubrication and maintenance, a high-quality ejector sleeve can withstand prolonged exposure to high injection pressures and elevated mold temperatures, ensuring consistent performance over its lifespan.

The ejection process in molding is more than simply pushing a part out of the mold; it requires precision engineering to prevent defects. An ejector sleeve is positioned concentrically around the core pin or within the mold cavity. When the ejection system is activated, the sleeve moves forward, pushing the molded part away from the core while maintaining its internal shape.

This process minimizes part distortion, reduces the risk of surface scratches, and improves cycle times. Since many plastic and metal molded components have delicate internal geometries, the uniform pressure applied by an ejector sleeve helps maintain consistent wall thickness and prevents warping. In industries such as automotive, electronics, and medical device manufacturing, even minor deformation can lead to assembly issues or part rejection, making the ejector sleeve’s role vital.

Furthermore, ejector sleeves are engineered to work in environments where temperature variations are extreme. During the molding cycle, mold cavities and cores undergo repeated heating and cooling, which can cause dimensional changes. Materials like SKD61 tool steel are chosen for their ability to resist thermal fatigue, ensuring the sleeve maintains its dimensional accuracy over thousands of cycles.

A high-performance ejector sleeve offers a combination of mechanical strength, heat resistance, and precision machining. Below are the most notable features and benefits:

Ejector sleeves are subject to constant friction during operation. Premium-grade steel alloys, heat-treated for hardness, allow the sleeve to resist surface wear even under high-cycle production. This ensures minimal dimensional deviation and consistent performance over time.

In injection molding and die-casting, mold components must withstand molten plastic or metal temperatures ranging from 200°C to over 700°C. High-grade tool steels used in ejector sleeves resist softening and maintain their structural integrity in these demanding environments.

Ejector sleeves are manufactured to exact tolerances to ensure smooth sliding action and precise ejection. The inner bore and outer surface are ground to achieve a low friction coefficient, reducing the need for frequent lubrication.

They can be customized in terms of length, diameter, and wall thickness to match specific mold designs. This adaptability makes them suitable for a wide variety of applications, from small precision parts to large industrial components.

A properly designed and maintained ejector sleeve reduces wear on surrounding mold components, preventing costly downtime and repairs. This makes them a cost-effective choice for manufacturers aiming to maximize productivity.

Material selection plays a major role in the durability and performance of ejector sleeves. The table below summarizes common materials and their properties:

| Material Type | Key Properties | Typical Applications |

|---|---|---|

| SKD61 Tool Steel | High heat resistance, excellent toughness, wear resistance | High-pressure die casting, plastic injection molds |

| H13 Tool Steel | Good thermal fatigue strength, high hardness after heat treatment | General-purpose molds with moderate thermal demands |

| Stainless Steel | Corrosion resistance, moderate wear resistance | Food-grade or medical mold applications |

| Carbide Coated | Extreme hardness, exceptional wear resistance | High-wear molds with abrasive materials |

Among these, SKD61 is particularly favored for its balance of toughness, heat resistance, and machinability, making it ideal for high-cycle, high-temperature environments.

Ejector sleeves are used wherever molded parts require precise removal without damage. Common applications include:

Automotive Components – such as gears, housings, and interior fittings where high dimensional accuracy is crucial.

Electronics and Electrical Components – including connectors, casings, and heat sinks that must maintain tight tolerances.

Medical Devices – for delicate components like syringes, diagnostic housings, and surgical instruments that demand defect-free production.

Consumer Goods – in manufacturing items such as bottle caps, kitchen tools, and appliance parts where high-volume production is essential.

Aerospace and Industrial Equipment – where components must meet strict quality and durability standards.

The versatility of ejector sleeves means they can be adapted to different mold types, materials, and production environments, making them indispensable to manufacturers across multiple sectors.

Even the highest quality ejector sleeve requires proper maintenance to ensure long-term reliability. Neglecting regular care can lead to issues such as galling, excessive wear, or seizure.

Best practices for maintenance include:

Regular Cleaning – Remove debris, plastic residues, and oxidation to prevent surface damage.

Lubrication – Apply mold-safe lubricants to reduce friction and wear.

Inspection for Wear – Monitor dimensions and surface finish to detect early signs of deterioration.

Proper Storage – When molds are not in use, store ejector sleeves in a clean, dry environment to prevent corrosion.

Avoid Overheating – Excessive mold temperatures beyond the sleeve’s material limits can cause softening and premature failure.

A well-maintained SKD61 ejector sleeve can last for hundreds of thousands of cycles, making it a cost-effective investment for high-volume manufacturers.

Q1: What is the difference between an ejector pin and an ejector sleeve?

An ejector pin is a solid rod used to push parts out of a mold, while an ejector sleeve is hollow and fits around a core to eject parts with internal cavities. Sleeves provide even pressure and reduce part deformation.

Q2: Can ejector sleeves be repaired?

Minor surface wear can sometimes be polished, but severe damage often requires replacement to maintain mold accuracy and prevent defects.

Q3: What is the best material for an ejector sleeve?

SKD61 tool steel is widely regarded as one of the best choices for high-temperature, high-volume molding applications due to its excellent wear resistance and toughness.

Q4: How do I choose the right ejector sleeve size?

The size depends on the mold design, core dimensions, and required clearance. Manufacturers typically provide specifications based on the mold’s engineering drawings.

Q5: How often should ejector sleeves be replaced?

Replacement intervals depend on production volume, material type, and maintenance practices. With proper care, high-quality sleeves can last for years without significant performance loss.

An ejector sleeve may appear to be a small, simple component, but it plays a vital role in ensuring the efficiency, accuracy, and quality of molded parts. From high-volume automotive manufacturing to delicate medical device production, ejector sleeves enable smooth, defect-free part removal while protecting the mold’s integrity.

Choosing a sleeve made from high-quality materials like SKD61, combined with precise machining and proper maintenance, ensures optimal performance over a long service life. For manufacturers seeking consistent results and reduced downtime, investing in reliable ejector sleeves is not just a tooling decision—it’s a strategic move to improve overall productivity.